International Graphite will provide Australia and its global manufacturing partners with high quality graphite products made to advanced technical specifications and exacting customer requirements.

Our global customers will have the confidence of knowing that our vertically integrated operations are based in Tier 1 jurisdictions, and built to the highest standards of ESG. because we have full product oversight and supply chain traceability and control. Our Collie Micronising Facility is expected to be operational in 2027 and product samples are currently available for customer testing. We have also announced plans for a new Expandable Graphite Facility, in Germany, to cater for the growing European market. In the future, we plan to produce a fully purified and coated battery anode material that will capture full value of the graphite resource from mine to market.

Micronised Graphite

Our Graphite Micronising Facility, at Collie in Western Australia, is the first of its kind in Australia and is due to be operational in 2027. Micronised graphite is used in a wide range of industrial products, including cathode additives for batteries, polymers, plastics, adhesives, ceramics and specialty lubricants. Pilot plant operations at Collie are currently producing product for customer qualification and acceptance testing.

Expandable Graphite

Expandable graphite is used as a flame retardant in construction materials, as insulation in electronics, and in batteries and green steel electrodes. Demand is accelerating as fire safety, energy efficiency, and high-performance computing drive growth across key industries. The new facility we are planning in Germany is targeted to produce around 3,000 tonnes of product a year and to be operational in 2027.

Spheroidised Graphite

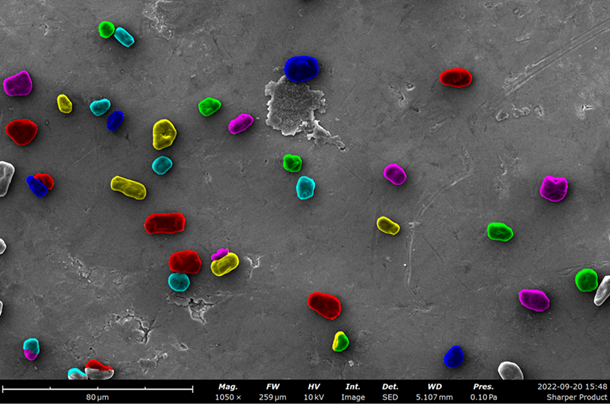

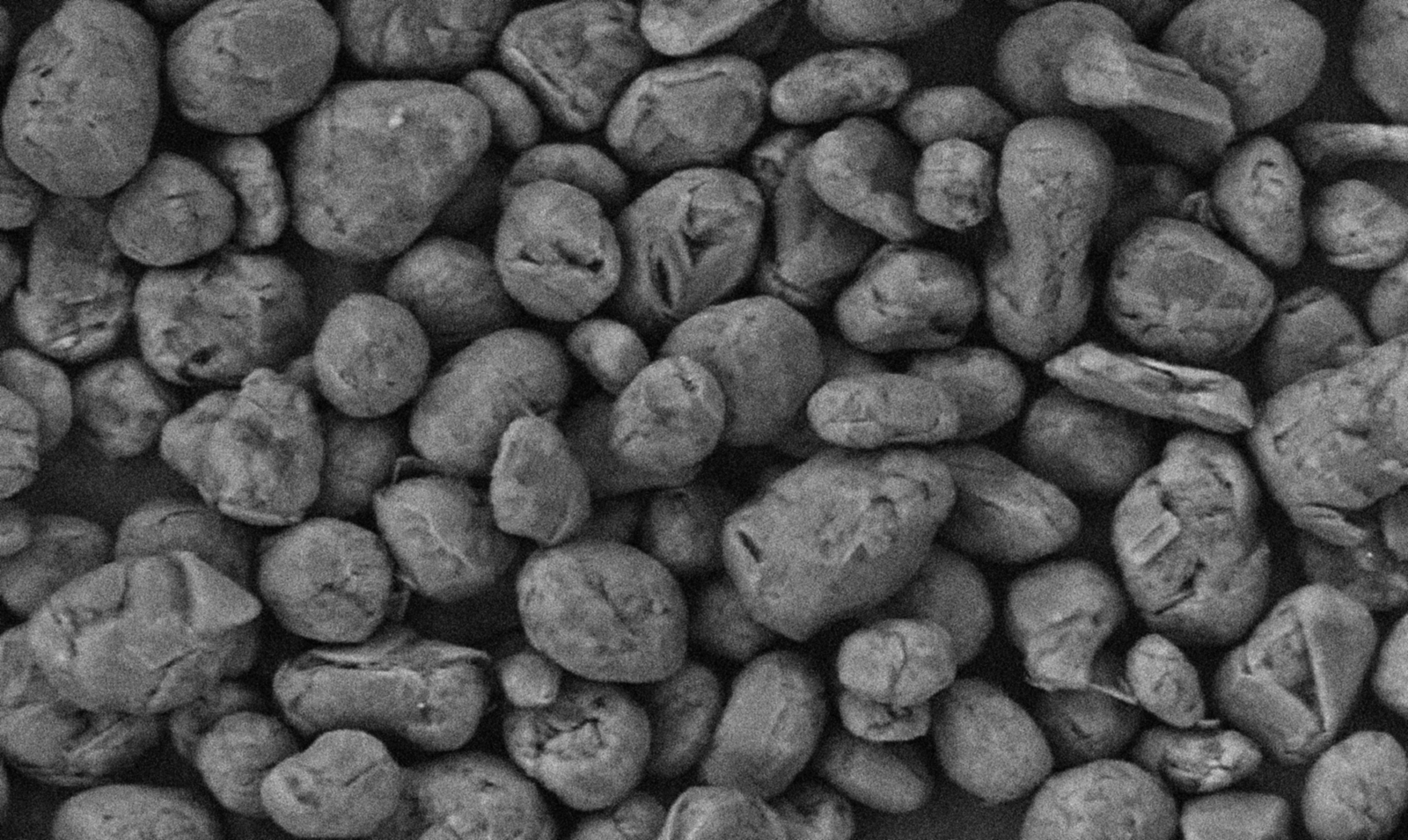

Scanning Electron Microscopy (SEM) analysis shows the high quality spheroidised graphite that has been produced at International Graphite’s research and development facility in Collie. This photograph shows the size of the spheroids and the well-shaped ‘potato’ particles from the pilot plant. These are highly desirable in a spheroidised product for battery anode production.

Battery Anode Material (BAM)

Ultimately micronised graphite from the Collie plant will pass through several refinement processes, including spheroidisation, purification and coating, to produce a premium active anode product used in the manufacture of batteries. Graphite makes up more than 90 per cent of the anode in a lithium-ion battery.

What is graphite?

Graphite is a naturally occurring form of crystalline carbon and a unique material that has both metallic and nonmetallic properties. This makes graphite an extremely versatile manufacturing material that has multiple uses, from lubricants, to refractories in steel making, and Lithium-ion batteries, as well as foils for computers and mobile phones, and expandable fire resistant building materials.

Graphite’s non-metallic characteristics include inertness and lubricity, as well as the ability to withstand extreme temperatures and chemical exposure, which makes it highly corrosion resistant. It is also an excellent conductor of heat and electricity making it sought-after for electronic products such as electrodes, batteries, fuel cells and solar panels.

Although graphite has been in use since 500BC, its remarkable potential is still being explored. A new supermaterial called graphene, above left, is one-atom-thick, flexible, transparent, conductive and more than a hundred times stronger than steel. Already scientists are investigating its use in micro electronics, folding computer screens, water filtration and as a superconductor for power and data.